(You can watch me glue up a ring on my YouTube Channel at “How I Glue up Segmented Rings.”)

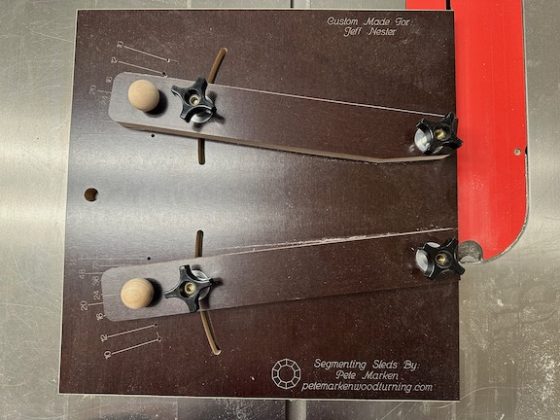

There are many different ways that people glue up segments. I use a method I learned at the Tennessee Woodturners Symposium. I learned this technique from Jason Swanson as he was demonstrating how to make a segmented pepper mill. His segments were 10″ tall and he only had one ring, but his technique still works well for short segments.

Jason used Titebond Original glue in his demonstration. I used that glue initially, but recently I was introduced to Titebond’s Speed Set glue. I prefer the speed set glue because it only requires 15 minutes of clamping time. Officially, you are supposed to let it set overnight before applying any stresses to the glue-up, but I have actually had great success putting the glue-up on the lathe 3 hours after applying the glue. So far, I have not had a joint come loose.

For my gluing technique, I start by laying a strip of tape down on a smooth work area with the sticky side up. My work area is a sheet of metal. To temporarily hold the strip in place, I fold back both ends of the tape and stick them down. I then place a strip of tape on both ends to keep the tape flat and tight. When Jason explained this method, he recommended that you use the cheapest masking tape you can buy. His point was: the cheaper the tape, the stickier it was.

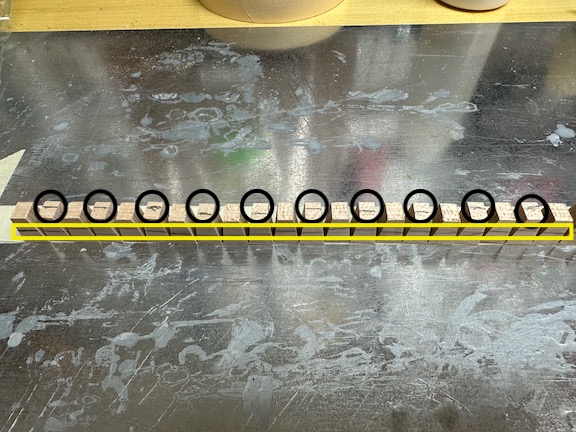

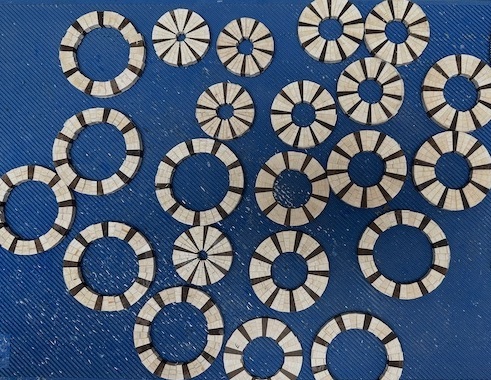

Now, place the segments one at a time, side-by-side, wide-edge-down on one edge of the tape. When using segments cut on a wedgie sled there will be lines on the edges of the segments and lines on the faces of the segments. When you place the segments on the tape, keep all lines on the faces facing the edge of the tape (Yellow box in Figure 3), and alternate the segments so that every other one has a line on its exposed edge (black circles in Figure 3.)

You might ask, “Why don’t I need to apply glue to the entire surface?” Well, when using this technique, the clamp applies enough pressure to the joint that the glue is forced all the way up to the thin part of the segment. As you can imagine, this is a very messy process and you will have a lot of glue squeeze-out, so make sure when you are putting the hose clamp on that you are on a non-stick surface. I use a Rockler glue mat, but wax paper works too.

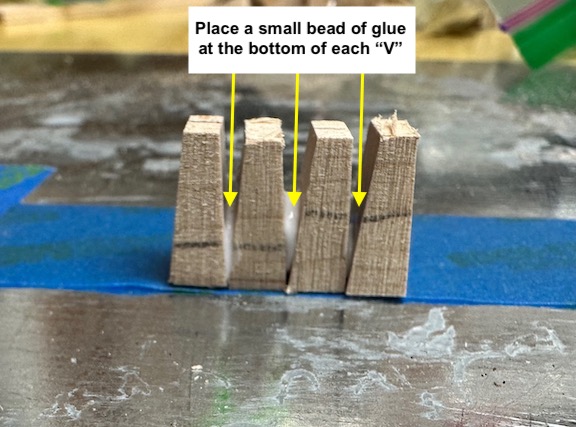

Once arranged, the secret to gluing up the segments is to place a small bead of glue at the bottom of each “V” (shown in Figure 4). Also, the very last segment needs glue applied to the outside of it since it will be glued to the first segment. Jason highly suggests counting each bead of glue so that you know you didn’t miss one when you get to the end.

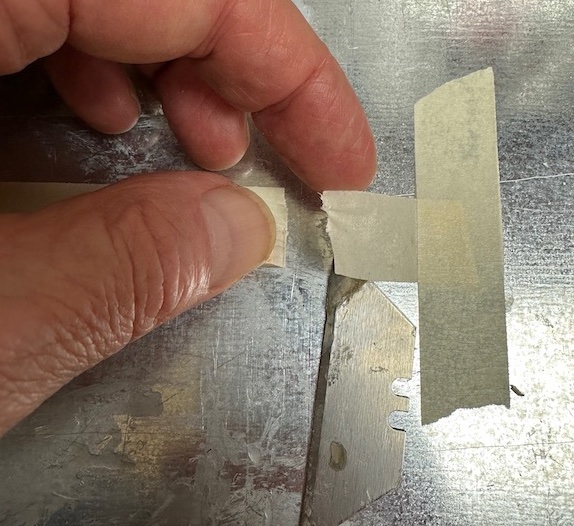

This next step deviates from Jason’s technique. With a pepper mill, you have long segments that you are trying to pull together so Jason leaves a long piece of tape at the end of each strip to wrap around the pepper mill to act as a temporary clamp until he gets the hose clamps on. Since my segments are small, a long piece of tape at the end makes it difficult to get the hose clamp around them. I take a razor blade and cut the tape off as close to the first and last segments as possible.

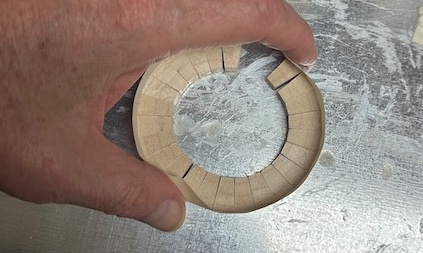

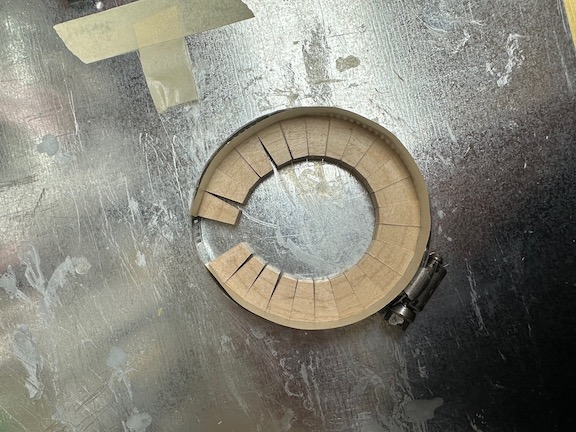

As soon as you have placed a bead of glue in every “V” and on the end piece, and cut off the extra tape, grab hold of the first and last segments and roll up the ring. You will find that the ring will not close but instead has a good sized gap; this is where the hose clamp comes into play.

Wrap the hose clamp around the ring and begin to tighten it down. (You will need to have the clamp open enough to fit around the ring with the gap.) Before you completely tighten the clamp, push down on all the pieces to get the ring as flat as possible.

When I do this the ring will be close to flat but not perfect, so I cut my segments a 1/16″ to an 1/8″ thicker than the final size and flatten them out with my thickness sander after gluing.

If you are using Titebond Original you should leave them in the clamp overnight. If you use the Titebond Speed Set you can remove the clamp after about 15-30 minutes.

When working with the Original glue you have a decent amount of working time before the glue starts to set up. With the Speed Set glue you have to move quickly. I have done this with 36 segments in a ring and have had very few issues, but you don’t have time to get interrupted. Once you start you need to finish quickly.

2 comments

I like your work. I have made several Thunderbird Feature rings, placing them in bowls and urns. Your spreadsheet will make my life a little easier while also making my work look better.

Thanks for sharing all your work

Larry Crouch

Louisville Area Woodturners, Louisville, KY.

Thanks! The spreadsheet helps a lot and the wedgie sled really makes a difference.